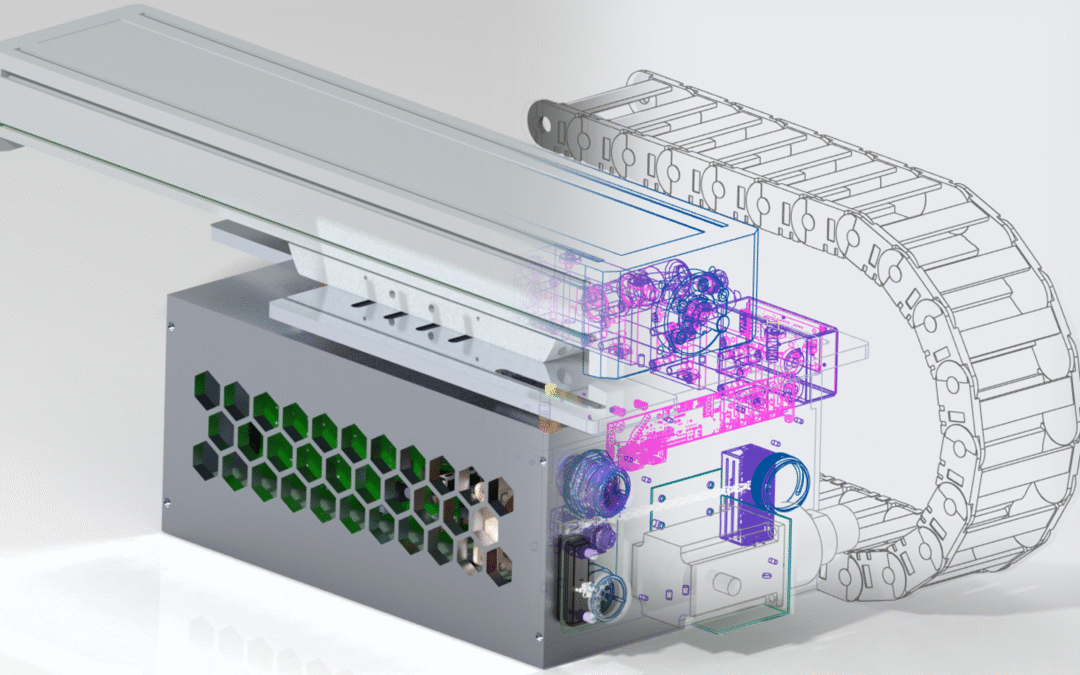

This precision engineering case study highlights how Atomik AM and Bibby Precision Engineering partnered to deliver over 100 custom metal parts with ±0.1mm tolerances in just eight weeks. The result was zero defects, full post-processing, and a showcase of collaboration done right.

Looking for the PDF?

View the Case StudyMeeting Tight Tolerances in a Precision Engineering Case Study

When Atomik AM required more than 100 custom metal parts for an advanced development project, there was no room for error. Each component had to meet strict tolerances of ±0.1mm and include full post-processing, all within just two months.

The Collaboration Behind This Precision Engineering Case Study

We partnered with Bibby Precision Engineering to meet these exacting requirements. Their team worked closely with ours to align on technical specifications, build sequences, and handoff protocols. This was not just a supplier relationship. It was a true engineering partnership built on collaboration and precision.

The Results of Our Precision Engineering Work

- Over 100 custom parts delivered on time

- Zero defects reported

- ±0.1mm tolerances achieved throughout

- Full post-processing and finishing included

With proactive communication, shared problem-solving, and meticulous attention to detail, the project delivered both speed and precision.

Why This Precision Engineering Case Study Matters

Working with trusted partners like Bibby Precision Engineering allows Atomik AM to move quickly while maintaining exceptional quality. This precision engineering case study shows how collaboration and technical expertise can accelerate innovation in advanced manufacturing.

Want to discuss a project with similar challenges? Contact the team.

View the Case Study