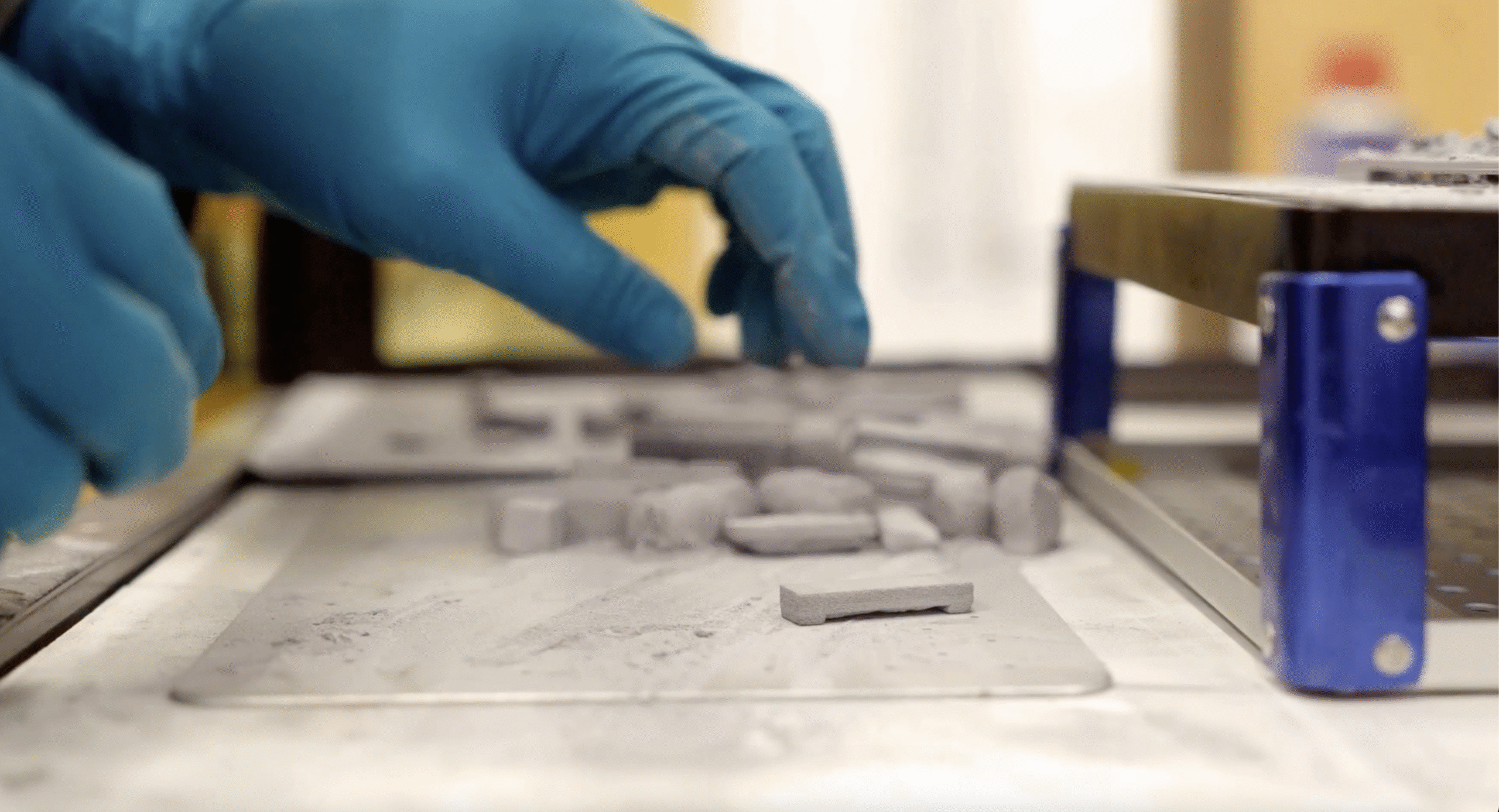

Binder jetting has been around for decades. The machines have improved, throughput has increased and material availability has expanded, yet many of the same limitations remain.

Green parts are still fragile. Automated depowdering is still difficult. Material behaviour still changes unpredictably between systems.

These challenges are often framed as machine or process limitations. In reality, many of them trace back to a quieter assumption: that the binder’s role is simply to hold powder together.

The binder as a passive component

In most binder jetting workflows, the binder is treated as a neutral adhesive. Its job is to temporarily bind powder particles until sintering takes over. Once that requirement is met, the binder is expected to disappear without influencing the final part.

This assumption has shaped how binders are formulated, selected and validated. Performance is judged primarily on printability and basic green strength, rather than on how the binder interacts with powders, process conditions and downstream steps.

The result is a system where the binder is present everywhere, yet designed to do very little.

Where limitations begin to surface

When binder jetting moves beyond controlled lab environments, the limits of this approach become clearer.

Green parts must survive handling, depowdering and transport. Powders must flow consistently through recoating systems. Shrinkage and distortion must be predictable rather than compensated for after the fact.

These behaviours are not governed by powder alone. They emerge from the interaction between powder, binder chemistry, saturation levels and processing conditions. Treating the binder as a passive ingredient leaves little room to control those interactions deliberately.

The binder as a functional material

A different approach is to view the binder as a functional material in its own right.

Rather than acting only as an adhesive, the binder can influence:

- Green part strength and failure modes

- Powder packing and particle interaction

- Sintering behaviour and densification

- Dimensional stability during thermal processing

This does not require speculative technology or radical hardware changes. It requires recognising that the jetted material is as much a part of the material system as the powder bed itself.

When binder chemistry is designed alongside powder characteristics, material behaviour becomes something that can be shaped, not just managed.

Universal and application-specific binders

This perspective also reframes the discussion around universal and custom binders.

A universal binder has value when it behaves predictably across machines, powders and workflows. That consistency lowers barriers to adoption and reduces risk during development.

However, some applications demand more. As requirements tighten around strength, density, surface finish or processing speed, application-specific binder design becomes a lever rather than a compromise.

The key is understanding when consistency is the priority and when functionality must be tailored. Both approaches rely on the same underlying principle: the binder is not neutral, and its role should be intentional.

Why this matters for scale

Binder jetting has long promised production-scale manufacturing. Speed and parallelisation make that promise technically plausible. What has held it back is not only hardware maturity, but the difficulty of achieving reliable, repeatable material behaviour at scale.

Recognising the binder as an active design variable changes how problems are approached. Instead of compensating for variability downstream, material behaviour can be influenced upstream, at the point where powder and binder first interact.

That shift does not solve every challenge in binder jetting. It does, however, unlock a set of tools that have been underused for far too long.

A quieter lever with outsized impact

The binder has always been present in binder jetting. What has been missing is the expectation that it should do more than hold particles together.

As the industry looks to scale beyond prototypes and pilot lines, material performance will increasingly be defined by how deliberately binders are designed, selected and validated.

Not as an afterthought, but as a core part of the material system.If you’re working with binder jetting and seeing similar limitations, the role of the binder is often a good place to start asking questions. Need to talk? We might be able to help.