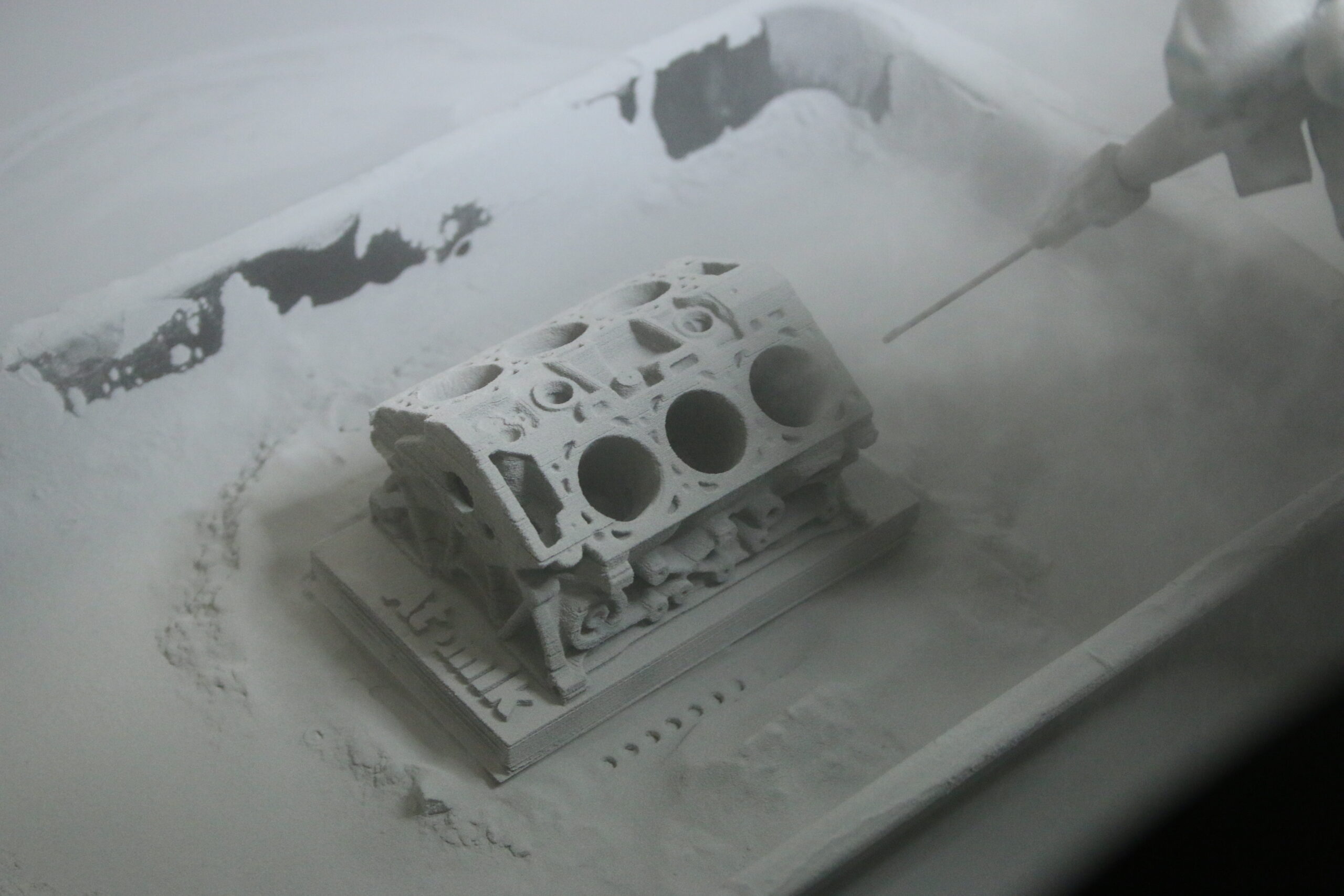

Validated Binder Jetting That Holds Together

Atomik develops and validates binders that deliver reliable green strength, consistent handling and repeatable performance across industrial binder jetting machines. Our solutions are built to reduce breakage, improve throughput and support reliable scale-up.

FROM VALIDATION TO CONFIDENT ADOPTION

Atomik helps manufacturers move from early testing to confident adoption of binder jetting technologies. Our expertise sits at the intersection of binder chemistry, machine behaviour and real-world manufacturing constraints.

We design and deliver validation programmes that give customers clear, decision-ready evidence. This includes demonstrating binder performance on relevant industrial printers, under realistic handling and production conditions, so teams can commit to materials and workflows with confidence.

Where required, Atomik supports this work with targeted printer optimisation and system-level adjustments to ensure reliable, repeatable results. The focus is always on outcomes that reduce risk and accelerate progress toward production.

What Our Expertise Delivers

Up to 40–60% reduction in binder cost compared to conventional binders, demonstrated during industrial validation

Zero curing time, enabling immediate handling and post-processing and improving throughput

Printhead lifetime extended to 12+ months, reducing downtime and maintenance overhead

High green strength, supporting manual handling and automated workflows without part failure

Measured improvements in yield and consistency, reducing scrap and rework during scale-up

A PRACTICAL ROUTE FROM FIRST PRINT TO PRODUCTION

Atomik works alongside engineering and manufacturing teams to turn binder jetting from a trial technology into a reliable production process. Engagements are focused, collaborative and grounded in real manufacturing constraints.

Whether the goal is to qualify a universal binder, develop a custom formulation or optimise performance on an existing machine Atomik brings together chemistry expertise, machine insight and application knowledge to support clear decision-making at each stage.

Projects are structured to minimise risk, generate usable outcomes and support long-term deployment rather than one-off demonstrations.

CLEAR ROUTES TO ADOPTION

Atomik supports manufacturers at different stages of binder jetting adoption, from early evaluation through to scaled deployment. Engagements are structured to deliver practical outcomes, whether that means qualifying a ready-to-use binder or developing a formulation tailored to a specific application.

Each route is underpinned by the same principles. Validation in industrial conditions, clear technical evidence and a focus on repeatable performance.

UNIVERAL BINDERS

VALIDATED, READY TO DEPLOY

Atomik’s Universal Binder range is designed for customers looking to improve performance, reduce cost and increase reliability without undertaking a full development programme. These binders are validated across industrial systems and materials and are available for immediate qualification and supply.

CUSTOM FUNCTIONAL BINDERS

DESIGNED FOR SPECIFIC APPLICATIONS

For applications that require tailored performance, Atomik works with partners to develop custom functional binders. Programmes are focused on delivering a working, validated binder within defined timelines, with a clear route to scale-up and long-term supply.