The future of sustainable manufacturing depends on smarter material use. At Atomik AM, we believe waste is simply a resource waiting to be reimagined. Through innovative collaborations, we are developing new ways to repurpose aluminium scrap into high-value materials, reducing waste and improving manufacturing efficiency.

One of our most exciting projects is our partnership with Cygnus Atratus, where we are working to turn aluminium waste from additive manufacturing into clean energy. This collaboration showcases how sustainable thinking can drive technological innovation and industry-wide change.

The Problem: Aluminium Waste in Additive Manufacturing

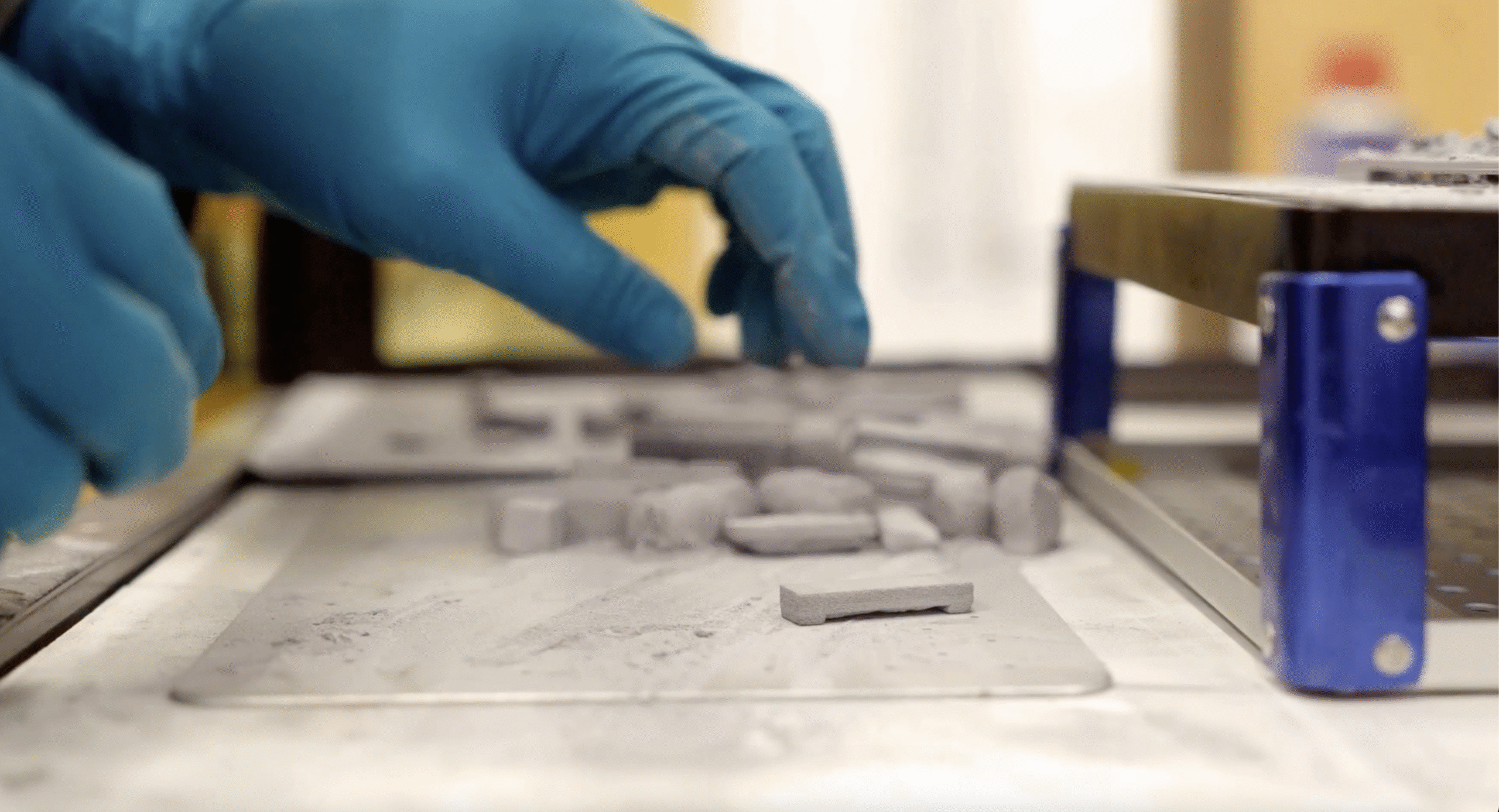

Aluminium is widely used in advanced manufacturing, aerospace, and automotive industries, but it comes at a cost. Traditional metal powder production is highly energy-intensive, and unused or excess powder often goes to waste. Many AM processes require high-purity, spherical aluminium powders, leaving non-conventional powders underutilised or discarded.

Without effective reuse strategies, this waste contributes to:

- High material costs for manufacturers

- Environmental strain from excess resource extraction

- Inefficiencies in the production cycle

Rather than treating waste aluminium as a by-product, Atomik AM and Cygnus Atratus are redefining its value.

The Solution: Turning Aluminium Scrap into Energy

Through our collaboration with Cygnus Atratus, we are developing a process that repurposes aluminium waste into a high-value energy source. Instead of discarding non-conventional powders, we are using them to generate clean hydrogen energy through aluminium-water reactions.

How It Works:

- Aluminium reacts with water to produce hydrogen gas, which can be used as a sustainable energy source

- The process is scalable, providing an alternative to traditional fuel sources

- By repurposing waste aluminium, we reduce the need for virgin material extraction

Why This Matters for Sustainable Manufacturing

This approach demonstrates a circular economy in action. Instead of relying on a linear supply chain where materials are used and discarded, we create a closed-loop system that extends the lifespan and functionality of materials.

Key Benefits of This Approach:

- Reduces industrial aluminium waste by repurposing non-conventional powders

- Creates a secondary revenue stream from materials that would otherwise be discarded

- Supports clean energy initiatives by producing hydrogen fuel

- Lowers the environmental footprint of metal powder production

A Step Towards Smarter, More Sustainable Manufacturing

At Atomik AM, we see waste as an opportunity. This collaboration with Cygnus Atratus is just one example of how interdisciplinary partnerships can unlock new, sustainable solutions for the manufacturing industry.

We believe the future of advanced manufacturing lies in smarter resource management, cross-industry collaboration, and sustainable material innovations.

Want to Learn More?

We are always exploring new ways to drive sustainability in additive manufacturing. If you are interested in collaborating or learning more about how waste can become a resource, get in touch with us.