A Solutions-Focused Approach to Advanced Manufacturing

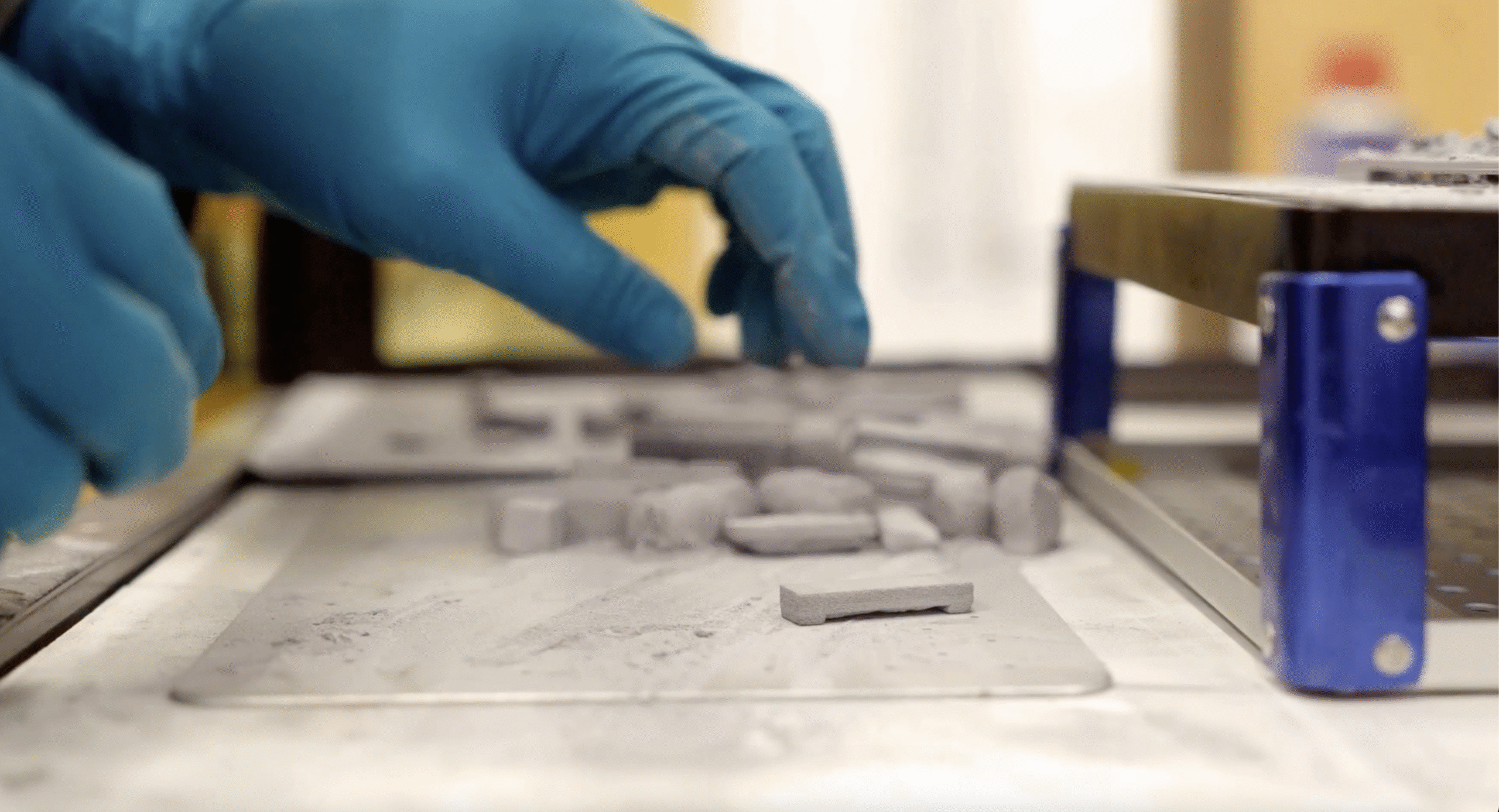

A MATERIALS-FIRST APPROACH TO BINDER JETTING

Atomik AM exists to help binder jetting move from promise to practical reality. We believe meaningful progress comes from understanding manufacturing challenges properly, questioning assumptions and applying the right expertise at the right stage.

Rather than starting with machines or processes, Atomik starts with the problem the binder must solve. By combining chemistry, engineering and materials science, we develop binder jetting solutions that address real production constraints and support confident, responsible scale-up.

Why Atomik AM?

CHEMISTRY AND ENGINEERING, WORKING TOGETHER

At the core of Atomik is the belief that chemistry and engineering must work together, not in parallel. Materials define performance, reliability and sustainability, yet they are often treated as secondary considerations.

By putting materials first, Atomik enables engineering decisions to be made with greater confidence. This integrated approach allows manufacturers to reduce risk, improve consistency and unlock applications that would otherwise remain out of reach.

Initial Consultation

Our journey together begins with an initial consultation. At Atomik AM, we take the time to understand your unique manufacturing needs and project goals. This step is crucial to ensure that our solutions align perfectly with your vision and objectives.

Project Analysis

Following the consultation, we conduct a thorough analysis of your project requirements. By assessing technical specifications and production challenges, we identify the most effective materials and processes to enhance your manufacturing capabilities.

Customised Solution Proposal

Once we’ve gathered all the insights, we present a tailored proposal outlining how our solutions can streamline your manufacturing process, improve efficiency, and reduce waste. We focus on delivering tangible benefits that align with your business goals.

Meet The Atomik AM Team

The driving force behind Atomik AM is our exceptional team of chemists, engineers, and business experts, all dedicated to pushing the boundaries of manufacturing and delivering innovative, sustainable solutions.

Professor Kate Black

CEO

Professor of Manufacturing at the University of Liverpool and serial advanced manufacturing entrepreneur, Kate’s vision for sustainable manufacturing is the foundation of Atomik AM. Her expertise in creating solutions that meet both business and environmental needs guides everything we do.

James McArdle

Chemist

James, with a PhD in synthetic organometallic chemistry, formulates novel materials for printing applications, carefully controlling the physical properties of printed parts to meet unique client requirements.

Connor Quilter

Researcher

With a PhD in material science and additive manufacturing, Connor works across engineering design, mechanical maintenance, binder jet printing, and binder formulation, offering expertise in a range of innovative technologies.

Kiran Southworth

Business Manager

Kiran oversees legal and financial regulations at Atomik. With a bachelor’s degree in business management, she ensures that the company’s finance, HR systems, and training needs run smoothly.

Oliver Rogan

Chemist

Holding a master’s in chemistry and a PhD in inorganic chemistry, Oliver creates effective formulations for Atomik’s bespoke and sustainable solutions, ensuring that our clients receive the highest level of innovation.

Daniel Potts

Senior Engineer

Daniel, with his integrated master’s in mechanical engineering, plays a key role in designing and maintaining the electrical systems used in Atomik’s printers, experimental rigs, and heat treatment machines.

Ian Jolly

CFO

Ian brings extensive experience in financial strategy and operational efficiency across diverse sectors. His leadership ensures Atomik AM’s growth aligns with its commitment to innovation and sustainable practices.

Meet The Atomik AM Board

Dr Simon Hart

Investor & Non-Executive Director

As Chief Technology Officer and Director at Innovation Catalyst, Simon supports companies in differentiating their technological innovations. His experience as part of the Oxford University spin-out YASA makes him an invaluable asset to Atomik.

Emma Nolan

Non-Executive Director

Emma is a technology transfer expert specialising in company formation, investment, and startup ecosystems. Her guidance supports Atomik AM’s growth and innovation.

Eric Solomons

Non-Executive Director

With a background in professional services, Eric offers deep financial and governance knowledge from various industry sectors, providing Atomik with a broad commercial perspective.