Looking back on 2025, this isn’t a list of milestones or announcements. It’s a reflection on what the year taught us about printing at scale, improving quality and working openly with the wider binder jetting community.

Much of the progress we’ve made this year came not from isolated successes, but from situations that exposed limitations, prompted questions and forced us to look more closely at how and why things behaved the way they did.

Learning Through Scale

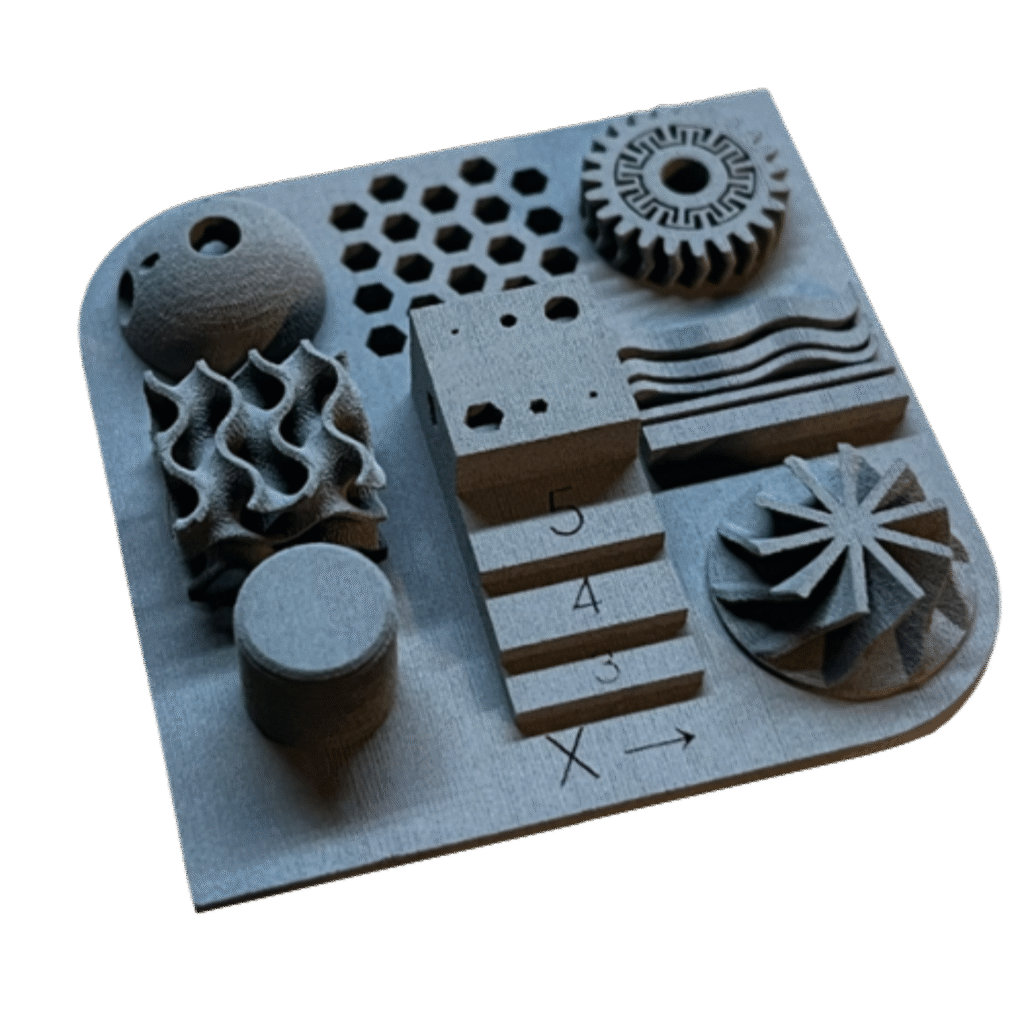

One of the most valuable moments of the year came during the Printathon. Printing at higher volumes and under tighter time constraints quickly highlighted where quality and consistency began to break down. Issues that can stay hidden during small-scale or controlled testing became obvious.

That experience was important. It shifted our focus away from individual prints and toward repeatability, process control and the interaction between binder, powder and machine conditions. The work that followed was driven directly by those observations.

Improving Print Quality

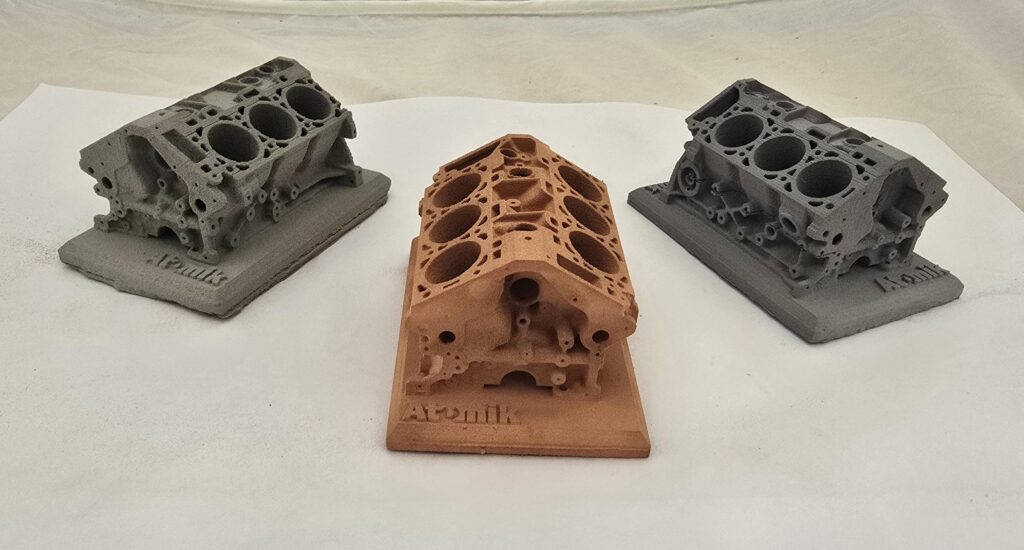

The learnings from early 2025 fed into ongoing refinement of formulation, print parameters and process discipline. Rather than chasing isolated performance metrics, the focus was on reducing variability and improving overall print quality across runs.

The difference between where we started the year and where we finished is noticeable, not because of one breakthrough, but because of many small, deliberate changes informed by real printing experience.

Working Across Different Environments

A significant part of 2025 was spent outside the lab. We travelled across Europe and to Canada to spend time with partners and customers, seeing how binder jetting operates in different production environments.

Those conversations and site visits reinforced how varied real-world setups can be, and why assumptions based on a single machine or workflow rarely hold. They also helped shape how we think about compatibility, validation and the role of a Universal Binder in practice.

Sharing and Testing Ideas Publicly

This year also involved contributing more actively to the wider technical conversation. Through editorials in publications such as PIM International, we shared aspects of our thinking around materials, binders and industrial adoption.

Opening that work up to external scrutiny helped sharpen our own approach. The feedback, questions and discussions that followed were as valuable as the act of publishing itself.

Representation and Responsibility

Alongside the technical work, 2025 also brought moments that sat outside the lab but still mattered deeply to how we see our role as a business.

One of those was the opportunity for our CEO, Kate Black, to take part in the inaugural UK–Ireland Summit roundtable in Liverpool, sitting alongside political leaders and fellow business owners to discuss trade, collaboration and manufacturing across the two nations.

For a growing SME, being present in rooms like that isn’t about profile. It’s about making sure the realities of manufacturing, materials development and scale-up are represented in wider conversations that often happen at a distance from the factory floor.

Those experiences reinforced something we’ve felt throughout the year: that materials innovation doesn’t exist in isolation. It sits within supply chains, policy decisions and international collaboration, and it carries responsibility as well as opportunity.

Being able to contribute to those discussions, while continuing the day-to-day work of printing, testing and refining, is something we’re proud of.

Looking Ahead

What 2025 reinforced above all else is that progress in advanced manufacturing is incremental and collaborative. Better prints come from better understanding, and better understanding comes from testing, questioning and sharing work openly.

The way we approach printing, validation and collaboration going into 2026 is shaped by what we learned this year. That learning continues.

We’re grateful to the partners, customers and peers who took the time to engage with us, challenge assumptions and contribute to the conversation along the way. We have a busy start to 2026 but if you’re looking for expert binder support, reach out to us!