Binder jetting succeeds or stalls on the printhead. If the head and binder are not a match, yield drops, reliability suffers, and costs rise. Many teams still run hardware that limits chemistry and process control. The result is slow progress and unpredictable outcomes.

At Atomik AM we teamed up with Gareth Neil at GN3DC to look at why this keeps happening and how to move forward. Gareth brings hands-on experience across research and production, which keeps the guidance practical and focused on real results.

Download the WhitepaperThe Hidden Constraint in Many Binder Jet Systems

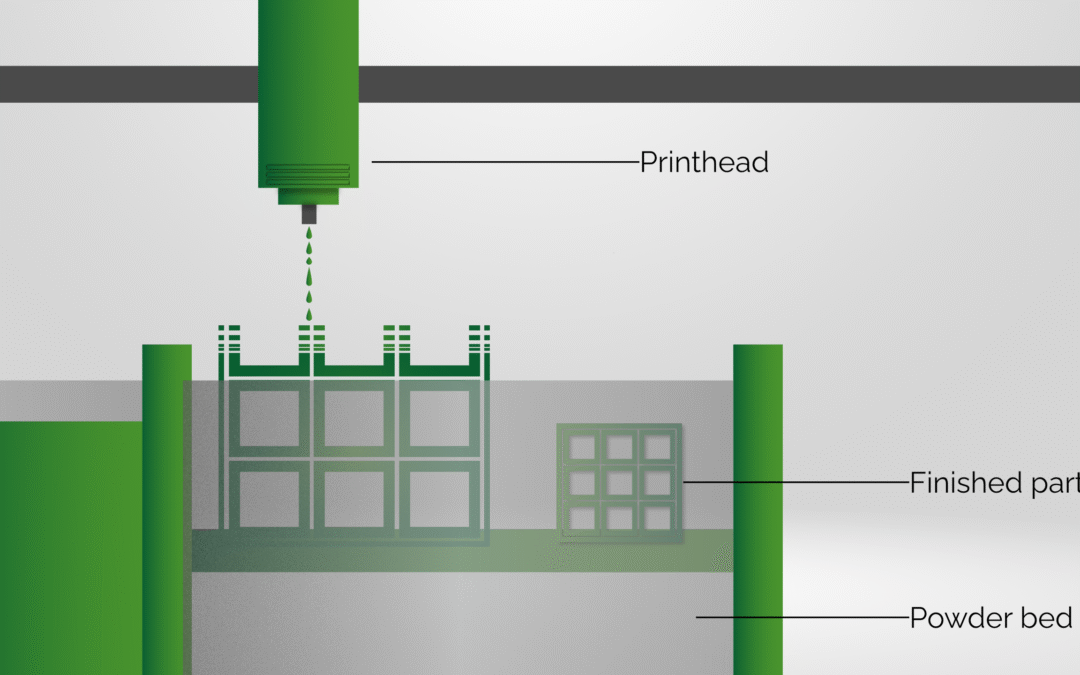

The printhead defines the droplets that shape every layer. It sets drop volume, frequency, placement, and the temperature window you can use. If the head cannot stably jet your binder, you end up compensating with slower builds, more cleaning, and more scrap. That is not a process problem. It starts at the head.

Why The Head and Binder Must Be Chosen Together

Binder chemistry and printhead materials interact. Viscosity limits, solvent choice, surfactants, and inhibitors all influence jetting, nozzle wetting, and lifetime. When the head comes first and the binder is forced to fit, chemistry is constrained and the process inherits the wrong limits. When both are developed together, stability improves and scale-up gets simpler.

Thermal and Piezo At A Glance

Both technologies serve valuable roles. Thermal heads can be a good fit for certain low viscosity systems. Piezo heads support a wider viscosity range and a broader solvent set. The right choice depends on your binder family, your feature size, and how hard you plan to run the machine. Our whitepaper explains how to compare these options in a structured way so you can make a confident decision.

What To Measure Before You Commit

Before you lock in a head, define your targets and test with your actual binder. Focus on uptime between cleans, nozzle redundancy, flushing volumes, and the cost of replacement. Track these numbers against yield and build rate rather than the unit price of the head. The cheapest head rarely delivers the lowest cost in production.

Why This Matters Now

Binder jetting is moving from lab success to production proof. That transition demands predictable yield and simple maintenance. Getting the printhead decision right sets a foundation that makes everything else easier, from drying strategy to sintering.

Get The Full Guidance

We have captured the practical decision points in a concise whitepaper created with Gareth Neil at GN3DC. It shows how to frame the choice, how to avoid common traps, and how to align head capability with binder chemistry and production goals.

Download the Whitepaper