Move Faster with Customer Innovation Projects (CIP’s)

In today’s fast-paced manufacturing world, innovation is the key to staying ahead. With Atomik AM’s Customer Innovation Projects (CIPs), you can move faster, drive efficiency, and achieve your business goals by outsourcing your innovation to a team that understands your needs and brings your vision to life.

What Are Customer Innovation Projects?

Customer Innovation Projects are collaborative partnerships where Atomik AM works with you to develop tailored solutions for your most challenging manufacturing problems. Whether you’re looking for advanced materials, machine design, or a hybrid approach combining both additive and subtractive manufacturing, our CIPs are customised to meet your specific needs.

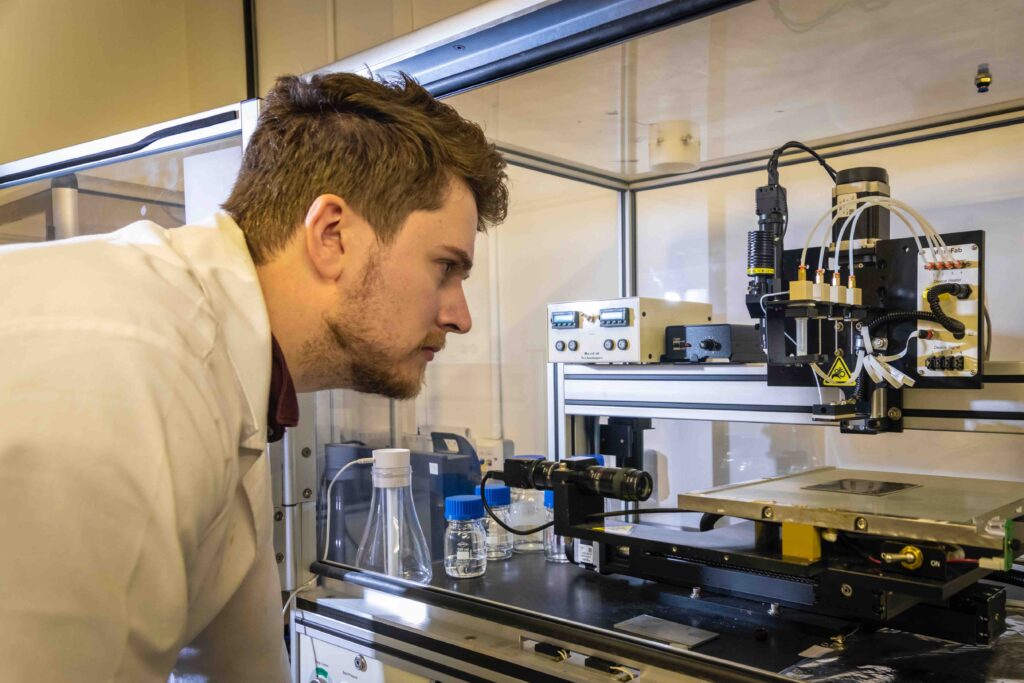

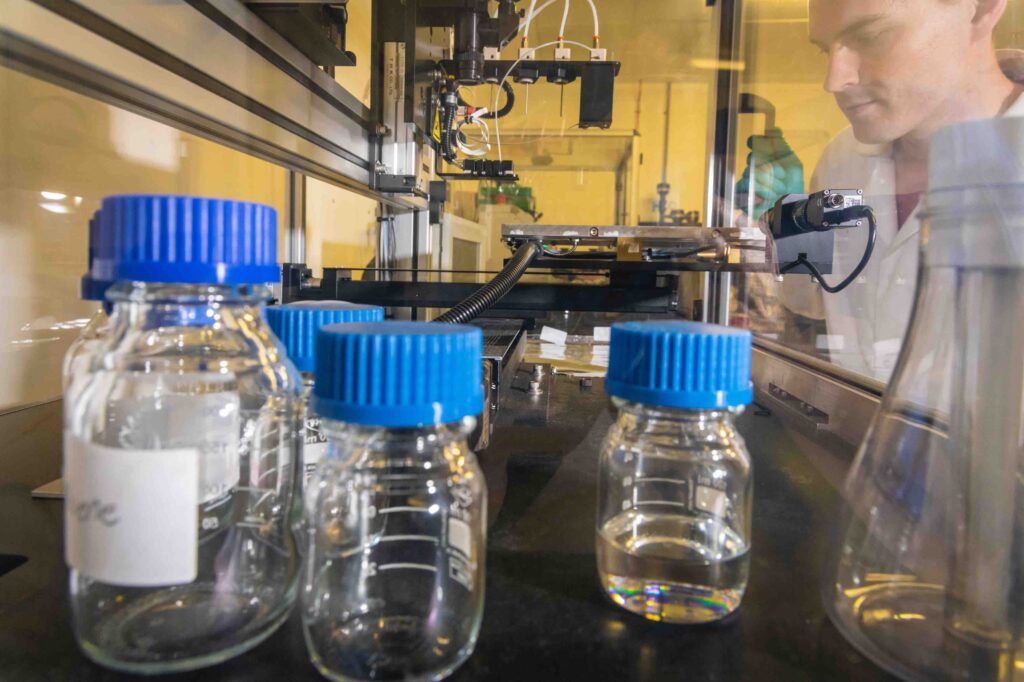

We start by understanding your unique challenges, then use our expertise in material manipulation and cutting-edge manufacturing technologies to deliver functional, innovative solutions that elevate your products.

How We Work:

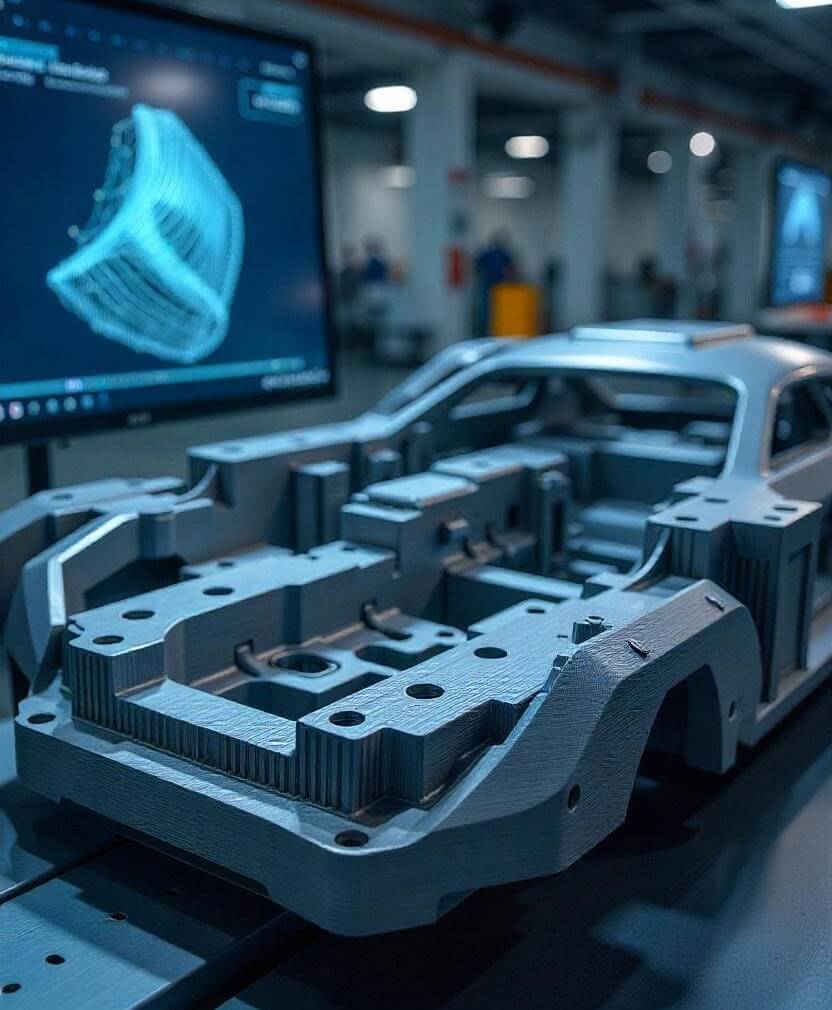

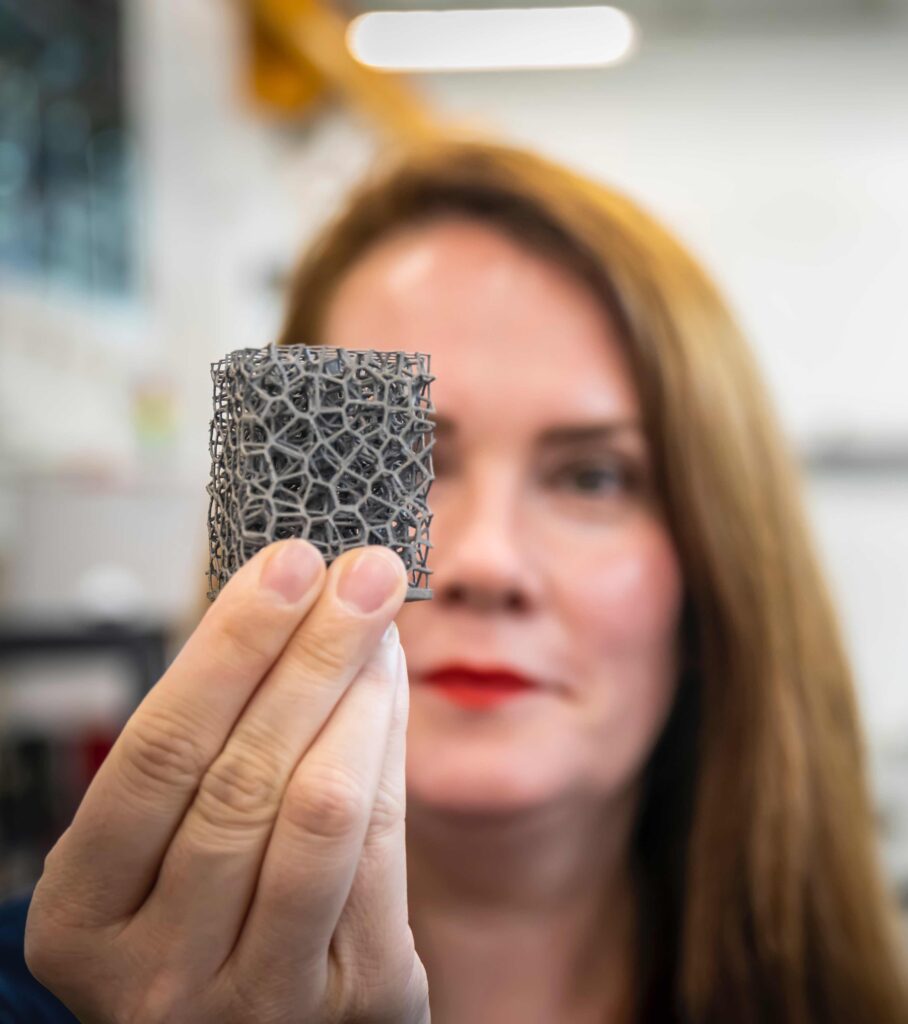

- Develop the Solution: Using our advanced expertise, we manipulate materials at the molecular level to deliver functionality that meets your needs at the product level. We leverage a hybrid of additive and subtractive manufacturing to create bespoke designs, from next-generation heat sinks to printed metallic components and beyond.

- Define the Challenge: We collaborate with you to clearly define your project goals, whether it’s enhancing product performance, reducing waste, or developing entirely new materials.

- Optimise for Success: Once the solution is developed, we work closely with you to ensure it’s optimised for maximum performance, scalability, and sustainability.

What We Can Do?

Our CIPs are as varied as your imagination. Here are just a few examples of how we can help:

Material-Driven Innovation: Marry architecture and material functionality to develop products that exceed current industry standards.

Next-Generation Heat Sinks: Create bespoke 3D designs that enhance performance and aesthetics, using innovative material functionality.

Large-Scale Metallic Components: Push the boundaries of size for printed metallic parts, such as car chassis or complex structural components.

Why Choose Atomik AM for Your CIPs?

Long-Term Partnerships: We don’t just deliver a project and leave—we partner with you to drive ongoing innovation and success.

Custom Solutions: We tailor every CIP to fit your specific needs, ensuring you get the exact functionality and performance you require.

Advanced Technologies: With expertise in manipulating materials at the molecular level, we deliver cutting-edge solutions that give your products a competitive edge.

Sustainability: Atomik AM prioritises sustainable practices in every CIP, helping you reduce waste and improve efficiency.

Let’s Build Your Next Innovation Together

Ready to accelerate your innovation? Atomik AM is here to help you redefine what’s possible in manufacturing. Whether you have a fully scoped project or just an idea, we’ll work with you every step of the way to bring your vision to life.